BULU decorative wall panels are made of sanded magnesium oxide board with decorative layer attached. It is a new generation of green, non-combustible core material for decorative wall panels. The sanded surface and size are similar to MDF, LVT and SPC. In addition, it is waterproof, mildew-proof and embed-proof, and the material safety complies with European Reach regulations and does not contain formaldehyde, toluene and asbestos. The decorative layer can be PVC, HPL, aluminum skin, CPL, cloth, leather, wood skin, etc.

2440mm, 2550mm, 2700mm, 2800mm, 3050mm or customized

5-30mm

1200mm, 1220mm or customized

Square Edge, Tongue Edge, Tapered Edge

White, Grey,

PVC, HPL, Leather, etc

A1

| Availability: | |

|---|---|

A1 fireproof | High thickness tolerance | No burning, no smoking | Impact resistant | Moisture resistant | Heat resistant | Mildew resistant | Insertion resistant | Lightweight and easy to handle | Quick to cut and tighten screws | Chloride free | No corrosion to steel frames and screws | Asbestos free | 100% non-toxic | Recyclable building material | Can be applied with different decorative surfaces

| PVC | Rich and colorful selection of patterns, high cost-effectiveness, can be covered and closely spliced |

| Melamine Paper | High cost-effectiveness, the surface has high wear and scratch resistance |

| CPL | Wear and scratch resistance, burning resistance, moisture resistance, no discoloration, good bending can achieve the coating of special-shaped surfaces |

| HPL | Excellent physical properties such as wear and scratch resistance, burning resistance, moisture resistance, and no discoloration |

| Aluminium | Superior strength, light weight, weather resistance, impact resistance, 90-degree bending installation can form a closely spliced effect |

| Cloths | Replaces the traditional wall cloth hard and soft packaging process, combining beauty and safety and environmental protection performance |

| Leather | With the texture and touch of real leather, it can meet the pursuit of design beauty |

| Wood vener | With the texture and touch of real wood grain, it can meet the pursuit of design beauty |

BULU Magnesium Sulfate Decoration Wall Panel is an advanced building material designed for both functional and aesthetic applications. Made from magnesium sulfate (MgSO4), these panels offer a combination of durability, fire resistance, and sustainability, making them an ideal choice for interior wall cladding and decorative finishes in residential, commercial, and industrial spaces.

One of the key features of BULU Magnesium Sulfate Decoration Wall Panels is their exceptional fireproof properties. Classified as non-combustible, these panels do not contribute to the spread of fire, providing enhanced safety for buildings. This makes them particularly suitable for fire-sensitive areas, such as kitchens, hallways, and high-rise buildings.

In addition to their fire resistance, these panels are highly durable and resistant to moisture, mold, and mildew. This makes them perfect for installation in areas prone to high humidity, like bathrooms, kitchens, and basements. They maintain their structural integrity and appearance over time, even in challenging environments.

The panels also have excellent soundproofing qualities, providing noise reduction and contributing to a more comfortable indoor environment. They are easy to install and can be customized with various finishes, including paint, wallpaper, or other decorative coverings. Their smooth surface allows for easy maintenance and cleaning, further enhancing their long-term appeal.

BULU Magnesium Sulfate Decoration Wall Panels are also an eco-friendly option, as they are made from sustainable materials that are non-toxic and free of harmful chemicals like formaldehyde. This makes them a safe choice for people sensitive to chemicals, contributing to a healthier living and working environment.

Overall, BULU Magnesium Sulfate Decoration Wall Panels are a versatile, durable, and safe option for creating beautiful, functional interiors. Their fire resistance, moisture resistance, and eco-friendly properties make them a top choice for modern building projects.

Our BULU MgO fireproof board is made from high-end magnesium oxide powder, containing more than 70% inorganic matter and alkali-resistant high-strength fiberglass mesh. The board cures naturally by cold melting, requiring no energy. It is inorganic and has no toxic components. It does not contain formaldehyde, fly ash - ingredients commonly found in plywood, OSB, fiber cement and gypsum-based building materials. It achieves its superior strength and flexibility through the input of alkali-resistant high-strength fiberglass mesh, which gives our boards unique high-performance structural properties. Our boards use a low-energy manufacturing process that uses 50% less energy than competing building products and actually absorbs CO2 from the atmosphere during the exothermic curing process.

BULU MGO boards are ideal for a variety of fire protection solutions. Classified as A1 (non-combustible) materials according to the American standard ASTM E84, these boards will not contribute to the spread of fire, thus improving fire safety in building applications.

BULU MGO boards are formulated to minimize organic content, ensuring they can easily pass fire tests such as ASTM E 84-12 with excellent results. This low organic content contributes to their fire resistance and non-combustibility.

For non-combustibility, building regulations define materials that pass the fire test requirements of BS 476: Part 4: 1970 as non-combustible. In addition, materials classified as A1 according to ASTM E119 :2002 (Fire Classification of Building Products) are considered non-combustible.

BULU MGO Fireproof Board is easy to install, cut, drill, shape and fasten. It can be machined like wood and drywall, making it easy to score, snap and maintain. The boards are compatible with carbide tools, which produce clean, square cuts for a quality installation. Disposable cutters can also be used for scoring and snapping, which can cleanly cut fiberglass mesh. When using a saw with precise depth adjustment, such as a manual power saw, the boards can be cut directly from the pile without leaving marks on the underlying boards. Construction crews typically use pneumatic roofing nail guns to fasten wallboard, and screws, framing nails and siding nails can also be used. Cutting BULU MGO Board is easier than cutting fiber cement because it produces less dust. The boards will not break during installation or when the edges are fastened with screws.

Since 2010 Denmark has witnessed a great loss of over EUR100 million caused by unqualified MgO “sweating board”. Different from those, BULU MgO boards are halogenide resistant and will not sweat because of the soaking process, as shown in the video.

Our BULU MGO board is durable and breathable. Our board resists moisture extremely well. It has a natural ability to absorb and wick away moisture, making buildings heavier and more durable. It can replace oriented strand board (OSB), plywood, and gypsum board for all sheathing, siding, subflooring, and roofing applications.

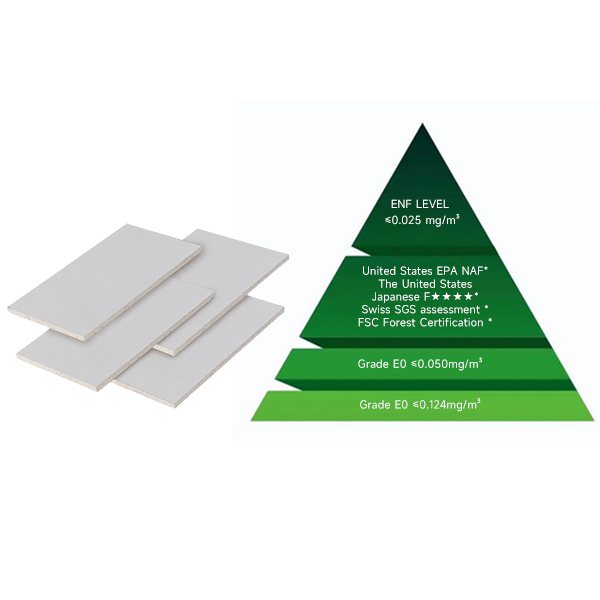

BULU MGO Fireproof Building Boards are free from harmful chemicals, gypsum, cement-based materials, and formaldehyde. Made from 100% sustainable and compostable materials, these boards are CO2 negative and breathable, contributing to a healthier indoor environment. Unlike many conventional building materials, BULU MGO Boards do not emit gases, making them ideal for individuals sensitive to chemicals. These boards comply with ENF standards, ensuring they meet stringent environmental and safety requirements. Their non-toxic nature makes them a safe choice for both residential and commercial applications, providing a safe, eco-friendly solution without compromising on performance.

BULU MGO Board is reinforced with 4 to 6 layers of high-tensile fiberglass mesh, providing exceptional bending strength of over 22 MPa and impact strength exceeding 38 MPa. This unique construction ensures superior tensile strength, making the board highly durable for various applications. The use of fiberglass mesh enhances the board's resistance to damage, offering a more robust and long-lasting alternative to traditional drywall.

Unlike conventional drywall, which is prone to surface wear, abrasions, and dents that require frequent cosmetic repairs, BULU MGO Board offers increased resistance to these issues. Its durability helps maintain a pristine appearance over time, reducing the need for ongoing maintenance and repair. The high impact and bending strengths make it an ideal choice for areas exposed to higher levels of wear and tear, such as commercial spaces, public buildings, and high-traffic areas.

BULU MGO Board can be combined with modern insulating materials (such as insulation boards and building membranes) for use in exterior building finishes. The board’s low thermal conductivity (0.0186 W/mK) and sound transmission value (30 dB) make it an effective barrier against both heat and noise. These characteristics help improve energy efficiency by reducing heat transfer and enhancing soundproofing, making BULU MGO Board an ideal choice for environments that require noise control and temperature regulation. Its superior performance in both insulation and soundproofing contributes to a more comfortable and energy-efficient indoor environment.

BULU MGO Board exhibits minimal expansion in both high temperature and extreme humidity environments, ensuring that its structure remains intact under a wide range of conditions. The board has excellent impact resistance, making it suitable for most industrial applications, even in challenging environments. BULU MGO Board is a sponge-like porous material that does not completely absorb water into its pores, leaving it with room to expand when frozen. This prevents any structural changes during freeze-thaw cycles. As a result, the board maintains its integrity and performance in cold conditions, ensuring long-term durability.

BULU MGO Board has an impressive dimensional stability, withstanding up to 50 freeze-thaw cycles with a loss in mechanical strength of only 0.5%, well below the permissible limit of 18%. This makes it a reliable material for applications where temperature fluctuations and high humidity are common, maintaining its structural and mechanical properties over a long period of time.

Rsetaurant

Hospital

Bedroom

Art Museum

living room

School

1. Construction leveling: According to the desian plan, level theinstallation wall and determine the distribution of the keel

2. Keel fixing: According to the distribution of leveling points, the keelis fixed on the wall with a spacing of ≤300m

3. Installation of internal anale profiles and plates: The internal analel, and the plate is inserted into theeel is fixed on the leveling keelinternal angle special keel

4. installation of intermediate profiles andplates: Fix the intermediate special profile and insert the plate

5. Installation piece by piece: install the lines and platesin sequence

6. External corner treatment: at the corner, first fix theexternal corner profile, then insert the plate

7. Accessory installation: after the wall is completed, youcan install the skirting and ceiling trim

Size |

Weight-KG/Piece |

Quantity 1 x Pallet |

Loading capacity in 20’ft CNT |

8mm x 1220 x 2440 |

26.2 |

100 pieces |

800 pieces |

8mm x 1220 x 2700 |

28.9 |

100 pieces |

800 pieces |

8mm x 1220 x 3050 |

32.7 |

100 pieces |

800 pieces |

10mm x 1220 x 2440 |

32.7 |

80 pieces |

640 pieces |

10mm x 1220 x 2700 |

36.1 |

80 pieces |

640 pieces |

10mm x 1220 x 3050 |

40.7 |

80 pieces |

640 pieces |

12mm x 1220 x 2440 |

39.3 |

67 pieces |

540 pieces |

12mm x 1220 x 2700 |

43.4 |

67 pieces |

540 pieces |

12mm x 1220 x 3050 |

49 |

67 pieces |

540 pieces |